Backflow Protection

A backflow prevention assembly is used to protect water supplies from contamination or pollution due to backflow.

In water supply systems, water is normally maintained at a significant pressure to enable water to flow from the tap, shower etc. When pressure fails or is reduced as may happen if a water main bursts, pipes freeze or there is unexpectedly high demand on the water system, the pressure in the pipe may be reduced and may allow contaminated water from the ground, from storage or from other sources to be drawn into the system.

Back pressure is another way that an undesirable contaminant may enter potable water piping. Sources of back pressure may be pumps in the water distribution system, boilers, heat exchanging equipment, or power washing equipment. In these cases there may be an almost constant risk of overcoming the static water pressure in the piping. To reduce the risk of contamination, a backflow preventer can be fitted. A backflow preventer is also important when chemicals are used, for instance for commercial/industrial descaling (boilers) or when bleaches are used for residential power washing.

To prevent contamination due to back pressure, some regulatory agencies require an air gap or mechanical backflow prevention assembly between the delivery point of mains water and local storage or use. Where submerged mains inflow is permitted a backflow prevention assembly is required, which protects the potable water system from contamination hazards. These hazards can be severe, some cases can be fatal. In many countries where regulations allow for the possibility of backflow, approved backflow prevention assemblies are required by law and must be installed in accordance with plumbing or building codes.

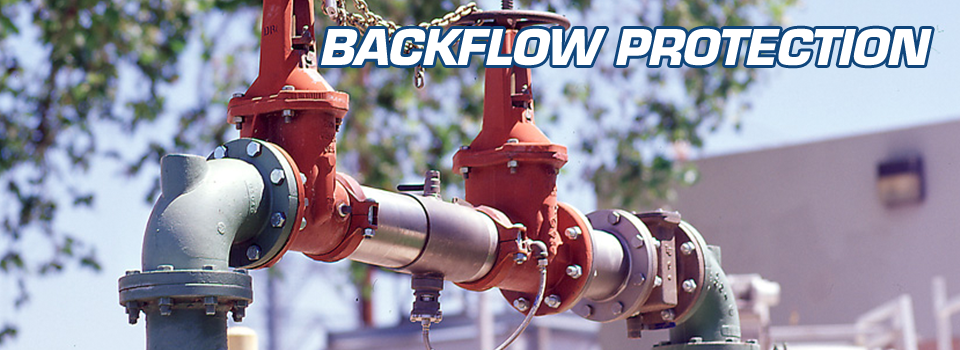

A typical backflow assembly has test cocks and shut-off valves and must be tested when installed, if relocated or repaired, and also each year.

In the United States, the Environmental Protection Agency (EPA) holds local water suppliers responsible for maintaining a certain amount of purity in potable water systems. Many states and/or local municipalities require annual testing of backflow prevention assemblies. A check valve is a common form of backflow prevention. In most cases, the law requires a double check (DC), n Reduced Pressure Principle Device(RP) device or an air gap when backflow prevention is mandated.